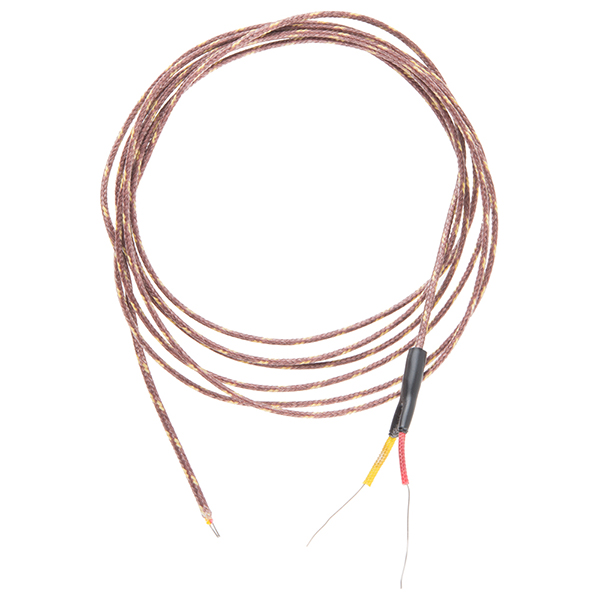

Thermocouple Type-K - Glass Braid Insulated (Bare Wire)

36" high temperature Type-K Thermocouple with glass braid insulation.

- Type-K Thermocouple (Ni-Cr)

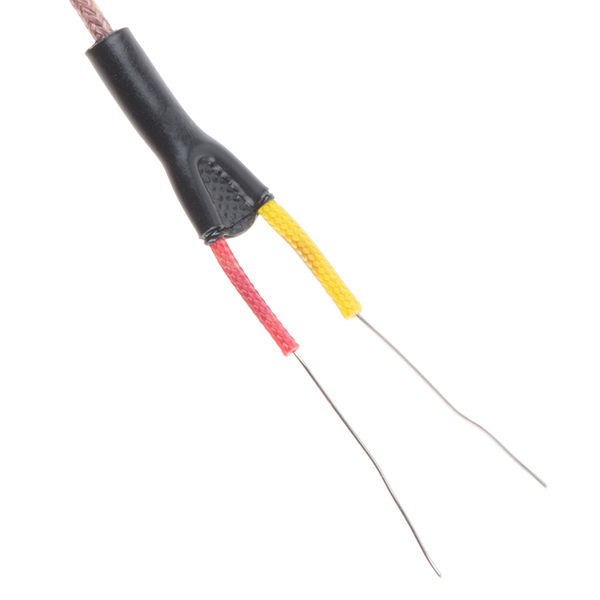

- 30 gauge stripped and prepped wires

- Thermocouple range : -270 to +1372C (-454 to +2501F)

- Glass braid insulation range : -73 to +482C(-100 to +900F)

- Yellow + / Red -

- Works great with our Thermocouple Amplifier AD595 IC!

Thermocouple Type-K - Glass Braid Insulated (Bare Wire) Product Help and Resources

MAX31855K Thermocouple Breakout Hookup Guide

November 5, 2015

Learn how to take readings with a k-type thermocouple using the MAX31855K cold-junction-compensated k-type thermocouple-to-digital converter.

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Noob - You don't need to reference a datasheet, but you will need to know basic power requirements.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

5 out of 5

Based on 1 ratings:

Worked great for my Makerbot Replicator Original!

The previous one had frayed, and it was a snap to put this new one on.

Is this waterproof?

[sarcasm] Great for those projects where I, um, need to sense those greater-than-2500F... [/sarcasm]

Actually, no, because the glass braid insulation would melt before then (900 ºF).

So my guess here is that there is a tip at the end? I need maybe like 8" of the length for the project I'm working on, and I'd hate to waste the other 2+ feet of thermocouple wire, but from looking at the picture and reading comments I'm guessing that it might make my project more complicated if I try to shorten it myself. Am I right?

For people that will be reading this in the future... Do not shorten the wire! It may drastically decrease accuracy. Please look up how thermocouples work before using one. I also recommend using a T-type instead, unless you need to measure extremely hot stuff.

AeroGuy is right. When you buy a thermocouple wire, the "sensing" part is just the very tip where the two metal wires are welded together. So if you cut the tip off, you'll be left with just two metal wires. They can't just be soldered together either. They must be welded together.

However, you can shorten the thermocouple at the other end, and it will work fine.

I have a problem with the K-type probe, the readings differ on LilyPad and UNO. UNO has the temperature right, LilyPad 20 degrees less. Any idea why is this happening? (of course the probe, code are the same)

Assuming you're using their built-in ADCs, do they have the same reference voltage? I don't remember if the ATmega328P has configurable internal reference voltage. Even if not, maybe one of them has a bad voltage reference circuit. Maybe also try using external reference voltage via the

Arefpin—though I don't know if the LilyPad breaks that out.what is the max temp of the glass braid insulation?

Somebody mentioned a data sheet, someone else said "see below", but I can't find it...

potentially a stupid question, but would this work if it was encased in silicone?

Maybe this has been mentioned already but I left the tip of the sensor outside while it was raining, overnight. Now it's not the same anymore. I can't get accurate temperature readings as a consequence. So, I would not recommend using this in any situation with moisture.

can I know if this sensor can be used to measure the human body temperature plz?

You sure can, but the data will not be reliable since the reading may vary by (at least) 2-3 C, which is a substantial amount when it comes to human body temperature.

oh yeah

You can submerge type K- it is Nickle-Chromel (positive) and Nickle-Alumel (negative) Type T, J you might not want wet- especially J (Iron/ Constatan) the max upper temp limit for 30ga type K is 1600F- 18 and heavier is 2000

for protection use a ceramic tube- other metals may affect the alloy in type K as different trace elements diffuse off at higher temperatures

wikipedia has great info on type K (and thermocouple), but the book to look for super specifics on thermocouple is ASTM e-230

I work for a thermocouple facility (and actually supply omega!) any questions feel free to ask!

Is there a datasheet for this Thermocouple?

yeah sorry i made a general post- look below!

Anyone know what the accuracy specs are for this? My hope is to use this to calibrate our home ovens, which seem to always take longer to cook food than recipes indicate. (I'm at a low altitude. The ovens' documentation has a snobby comment about how they're perfectly calibrated, thank you very much.)

yeah just use the thermocouple- the mfg has specific requirements it has to meet (EMF- eletro-motive force) (k cant vary more than .089mv from 200-500F)there are 32 mv/degree

if you are super concerned- look for a special limits sensor- it will cost a bit more but it is only allowed .044mv from 200-500

I need a sensor for use in a glass kiln that can achieve temperatures of up to 1800 deg. F. This sensor covers that range according to the specs, but the glass insulation is only good up to 900 deg. F. I don't get it. Why would you take a sensor that is rated to 2501 deg. F. and cover it with insulation only good to 900 deg. F. Am I missing something? Does one remove the insulation for higher temp applications, or is this sensor really not usable above 900 deg?

at 2501F you are going to need a very very expensive thermocouple- a type R/B to get those very high temps-

the thermocouple needs to be the only thing exposed-after you use it you can slide it in a little further and it will maintain its accuracy

This is a k rated sensor, however the probe tip is a tiny affair, it's the bit on the end of the insulation. On kiln temp sensors the tip is several inches long, this allows it to be inserted through the kiln wall without exposing the insulation to excessive heat.

You can find ones designed for kilns by searching "k temperature probe" on google

The short answer is probaly cost. The sensor functions at 2500 degrees but the materials may nit last long at high temperatures. Tcs made for that type of enviromemt are sheathed in high performance alloys. Most people won't need that. For your application checkout omega.com, there website is not very good so you may want to call.

Not sure if this is going to be much help.

Many years ago I worked at a metallurgical test lab. They basically tested samples of metal under high tensional stress along with high temperature. There was a guy whose sole job was building thermocouples that would sit inside a furnace to measure the temperature of the specimen under test.

He would take two pieces of dissimilar wire and spot weld them at one end to form the hot junction. To insulate the two pieces of wire from each other and from the outside world, he would thread ceramic beads onto the two wires.

Each ceramic bead was cylinder shaped, about 6mm in height and about 4mm in diameter. There were two small holes running through the cylinder.

The finished thermocouple was very fragile and needed great care during installation. It resembled a necklace of pearls. The goal though was that it could stand extremely high temperatures and was somewhat flexible for routing out of the furnace.

I'm afraid that I have no idea where to source the ceramic beads, or the bare al/ch wire to make a K thermocouple from scratch.

Ditto to this question!

This looks like the same as this thermocouple from McMaster-Carr

http://www.mcmaster.com/nav/enter.asp?partnum=9251T93

Note: You cannot solder to the ends of this thermocouple.

I have this TC... has anyone else used this? I'm using the MAX6675 TC amp and the arduino. All seems to work well. However I would like to use this TC under water. I was thinking of epoxying the very end of this TC into a small diameter stainless steel tube, but I'm not sure how this will effect it's accuracy. The temp range of the application is on the low side <200 degrees F. Any ideas? Would plastic work?

Stainless is a terrible conductor of heat. Epoxying this inside a SS tube would effective be insulating it from whatever you're trying to measure.

Although stainless conducts heats orders of magnitudes slower than pure copper or aluminum, that would really only have an effect on the response time of the system. It will reach the steady state temperature of the solution, but it may not represent the temperature of the solution exactly if the solution's temperature is varying rapidly. Stainless thermocouples are used all the time in both chemical and biological processes. Stainless still conducts much better than air. For comparison, aluminum's thermal conductivity = 250, stainless steel's thermal conductivity = 16, and air's thermal conductivity = .024 W/(mK).

http://www.engineeringtoolbox.com/thermal-conductivity-d_429.html

Any idea when it will be restocked? Can you say who its from?